HDPE ( HIGH DENSITY POLYTHYLENE)Home / Pipe Technology / HDPE

HIGH DENSITY POLYTHYLENE - IS 4984:1995

Installation Method

Polyethylene & polypropylene pipe or fittings are joined to each other by heat fusion or with the mechanical fittings. Plastics ay be joined to other materials by means of compression fittings, flanges or other qualified types of manufactured transition fittings. There are many types and styles of fittings available from which the user may chooose. Each offers it's particular advantages and limitations for each joining situation the user may encounter. contact with the various manufacturers is advisable for guidance in proper applications and styles available for joinin as describ in this document. There will be joining methods discussed in this document covering both large and small diameter pipe.

HDPE Material use & Characteristic

When compared to other plastics, PE shows excellent diffusion resistance, and because of this property, polyethylene has been successfully used for the safe conveyance of gases for many years. Polyethylene has good resistance to acids and caustic substances. Resistant to organic and inorganic solvents at a wide range of temperatures. It is not resistant to strong oxidizing acids.

Resistance to acids, caustic substances,organic and inorganic

solvents

Good material strength and fatigue

resistance

Operating temperature range -40 to 65 °C (-40 to 149 °F)

Mechanical compression joint up to 125 mm (4.921 in) or Fusion Welded

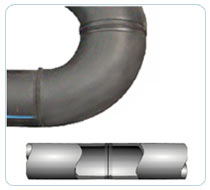

Butt Fusion

The principle of heat fusion is to heat two surfaces to a designated temperature, then fuse them together by application of a sufficient force. this force causes the melted materials to flow and mix, thereby resulting in fusion. When fused accordingg to the pipe and/or fitting manufacturers' procedures, the joint area becomes as strong as or stronger than the pipe itself in both tensil and pressure properties. As soon as the joint cools to near ambient temperature, it is ready for handling.

The 6 steps involved in making a butt fusion joint are:

Securely fasten the componets to be joined

Face the pipe ends

Align the pipe profile

Melt the pipe interfaces

Join the two profiles together

The 6 steps involved in making a butt fusion joint are:

Application Advantages

| √ Water Treatment | √ Outstanding Flexibility |

| √ Food & Beverage | √ High Impact Resistance even at very Low Temperatures |

| √ Water and Gas Utilities | √ Safe and Easy joining by welding |

| √ Shipbuilding | √ Excellent cost-Performance ration |

High Density Polythylene (HDPE)

The most widespread use of polythyne in pipeline construcion is for ground-layed gas and water pipes. But its benefits are also utilized in hoisehold technology and in industrial pipeline construction.